One example is its participation in developing the Madrid-Seville line,...

Leer másTechnology Innovation Awards 2023

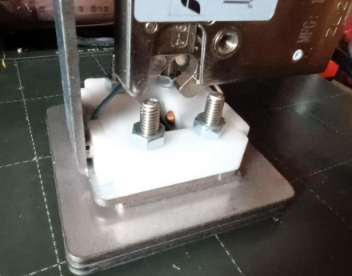

Chepro THL Nuclear System GLS1 (1 hour)

Innovations in the Purple Line Light Train

Control and management subcontracts at Latam Norte

3D printing in the bicycle loan service

Here are the winning teams in the latest OHLA Technological Innovation Awards, with projects that highlight the influence of OHLA and its affiliate companies in the fire-fighting sector, in the development of procedures for the efficient management of construction projects or in the application of technologies that make life easier for citizens:

Paulino Muñoz Ocaña, Pablo Arenas Muñoz and Carlos García Arráez, from the Castellón branch of Chepro (Spain), a subsidiary of OHLA specialized in fire protection systems, have won the first prize for the Best Technological Innovation in a Project for the development, certification and approval of a new product for fire protection under the high standards required in nuclear power plants.

In the tests carried out for its certification, this innovation kept the protected electrical installations below 120 ºC during more than one hour, compared to over 1,000 ºC recorded on the side exposed to fire.

The team responsible for the Purple Line Light Rail construction project in Maryland (USA) has won a second prize in the category of Best Technological Innovation in a Project, for devising and implementing unconventional solutions to reduce conflicts, permit procedures and risks of disruption, both to the Metro in operation and to citizens, services and adjacent work sites.

Diverse ingenious solutions have significantly reduced disruption to citizens, train traffic, vehicle traffic and nearby construction sites in a complex urban environment bordering Washington DC.

In the category of Best Digital Innovation in Internal Process, the award went to Jonathan Rafael Miranda Primera, José Alberto Rojas Díaz and Jorge Tomás Agulló Ortiz, for their project Control and management of subcontracts at Latam North, consisting of a unified system, developed in-house with low-code IT tools, for the efficient management of subcontracts in the area.

This system is already in place in two countries (and a third one is in process) and is beginning to show results in terms of more efficient management and control of our subcontractors.

The initiative 3D Printing in the Bicycle Lending Service, presented by Gonzalo Pérez Til and José Antonio González García, colleagues of Ingesan and representatives of UTE Bicicletas Albacete, has won the award for Best Innovation for Carbon Footprint Reduction. The initiative systematizes the use of 3D printing in combination with sustainable materials for the management of spare parts and service improvements.

80% reduction in the cost of purchasing and storing spare parts, manufactured on site with sustainable materials and greater durability.

One example is its participation in developing the Madrid-Seville line,...

Leer másTake a look at our greenest projects in the new...

Leer másHere are the winning teams in the latest edition of...

Leer más